Comprehensive equipment list to pass the iso audit the company must demonstrate that it has a comprehensive equipment list with controls in place for additions subtractions and custodianship of equipment.

Calibration of medical equipment ppt.

Calibration is then a very useful tool to improve measurement accuracy.

And quality assurance.

Device class and regulatory controls class i general controls lowest risk with exemptions limitations under 21 cfr parts 862 892 9 without exemptions required 510k for marketing.

Fda classifications classified 1 700 different types of devices and grouped into 16 panels.

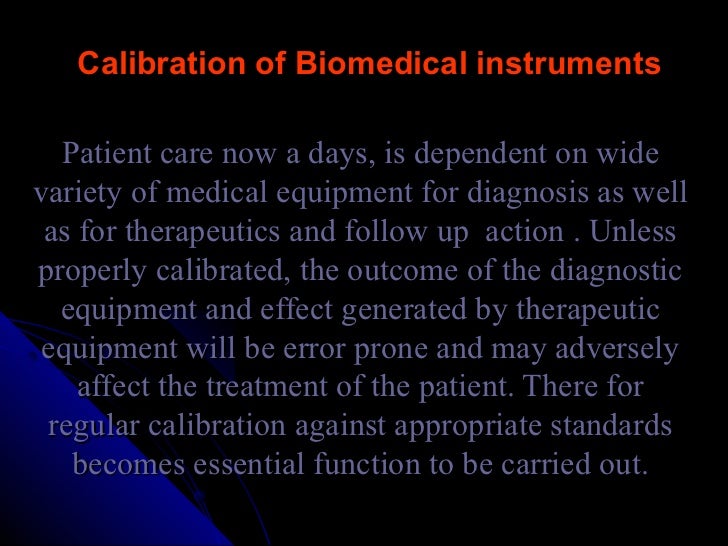

Calibration of medical devices and manufacturing equipment needs to be performed on a routine basis by trained and certified professionals.

We will arrange for a member of our experienced team to visit your site at a date and time convenient for you to calibrate and test any medical devices and equipment required.

Medical equipment calibration.

Patient treatment areas for all doctors physiotherapists dentists chiropractors and aged care facilities require specialised electrical work and stringent medical equipment testing which is compliant against as nzs 3003.

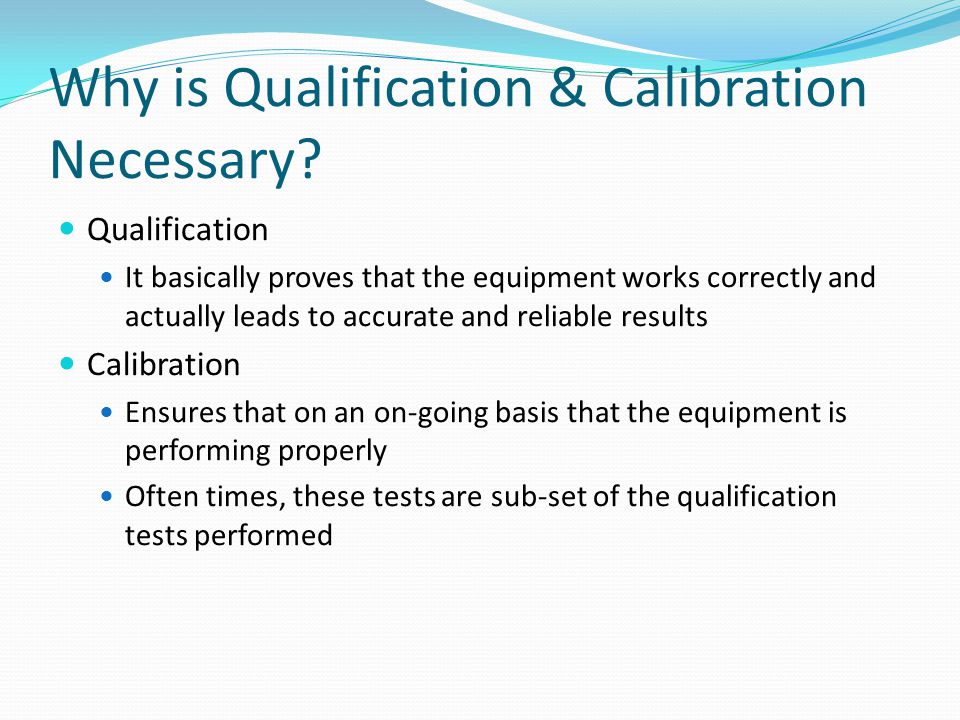

Calibration of such medical devices is important for two main reasons.

If errors are noticed adjustments and repairs need to be made followed by re calibration to verify the accuracy of calibrated equipment.

Hilltop hotel kigali rwanda.

Second it increases customer confidence.

We have decades of experience managing calibration programs in.

Pharos university in alexandria.

Calibration of medical equipment 4th east african regional healthcare engineering conference exhibition earc 2014 dates.

Accredited calibration lab the calibration laboratory must be iso 9001 2008 accredited or be the original equipment manufacturer.

Medical equipment management a proactive approach.

Medical equipment calibration calibration and asset management for medical device manufacturers.

Importance of calibration calibration of a measuring equipment or working standard enables the user to take note of the deviations and errors from the nominal values so that corrections can be made to minimize the errors during measurement.

17 thto 19 dec 2014.

A top priority for medical device manufacturers is the health and safety of patients and the accuracy and precision of the instruments used in production is of the utmost importance.

Each types is assigned to one of three classes based on the level of safety and effectiveness.

Medical equipment testing inspection calibration.